Descriptions of HCGP annealing machine:

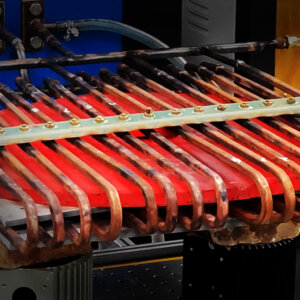

Based on the principle of electromagnetic effect, it can penetrate non-metallic substances and generate induction heating to any metal instantly in a non-contact form, so as to achieve the annealing function. Its advantages are high heating temperature, fast heating speed, energy saving and less oxidation, but the disadvantage is that the annealing depth is shallow, and for large metal parts, the annealing is not complete. High frequency annealing machine is suitable for metal surface annealing process.

1. Application: Induction annealing for rods, pipes, threaded bar and other parts.

2. Power output of machine: 10kW-200kW

3. Frequency of machine: 5kHZ-60KHz

Hongchuang automated Induction annealing equipment can be custom design with various loading and feeding method, high efficiency induction heating for variety of automation induction annealing process.

Features:

1. Annealing parts can be loading & feeding by rotary indexing table, manipulator, linear drive regarding to variety of annealing parts and process requirement.

2. Effective and precise heating control by PLC.

3. Uniform heating on material guarantee the quality of annealing.

4. Widely applied for induction annealing of tools, tube and pipe production.

Hongchuang High Frequency

Hongchuang High Frequency