Descriptions:

This Induction Hot Assembly equipment is adapt to core rod fitting into shaft with manual loading or robot arm loading , auto feeding, heating, fitting and integrated with automatic unloading and transmission system.

Features:

1. Automatic pressing mechanism ensure accurate fitting.

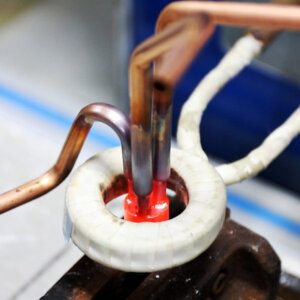

2. Shaft is induction heating, precise localize heat meet tight production tolerances.

3. Multiple-segment settings for induction heating: There are 5 segment basically and can be customized according to customer requirements.

4. Precise temperature control: In collaboration with the manufacturer,we have jointly developed infrared thermometers with a measurement accuracy of ±1% Measuring range; Closed-loop control system with PID controller, achieving precise temperature control during induction heating process.

5. Accurate heating: Heating time can be accurate to 0.1 seconds.

6. Data Storage: Multiple process parameters storage with one-click for data retrieval

Advantages:

1. Simple Operation and lower requirement on operator

2. Automation Press system improve products consistency

3. Increase products pass rate with reliable heating and fitting

4. Meet production rate with fast heating

5. Customization is available for different type of shaft shrink fitting process.

Hongchuang High Frequency

Hongchuang High Frequency