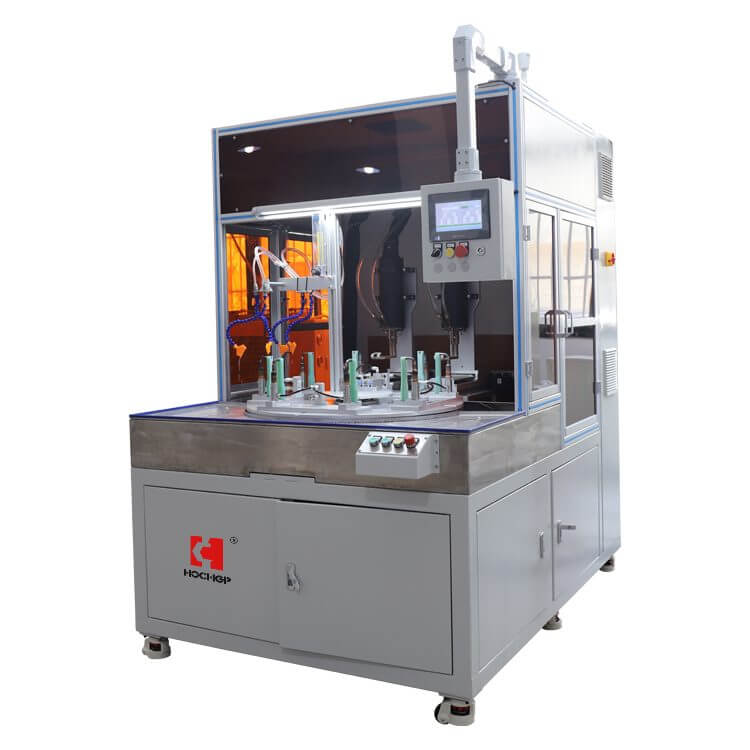

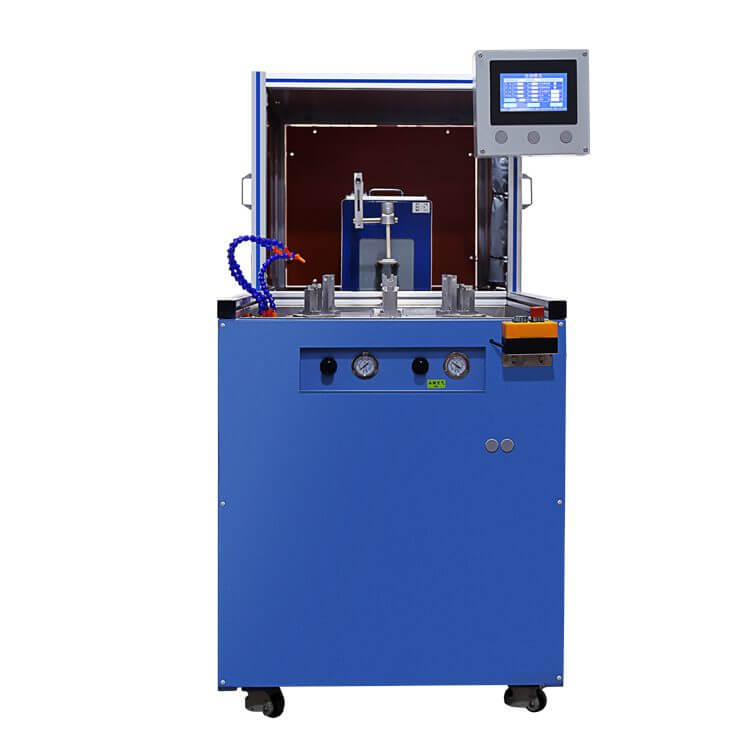

This Induction brazing machine is integrated design with turn-table feeding, automatic brazing, soldering flux feeding automatically during brazing process, automatic cooling, and manual loading & unloading, auto feeding.

Features

- Induction brazing machine can be manual, semi-automatic or automatic according to customer’s need.

- Working station of induction tube brazing machines are customized single station, two stations and multiple stations to meet different production rate requirement.

- PLC control let induction brazing machine easy to control heating power, heating time and brazing location.

- Particularlydesign ensure successful brazing process such as inert gas for operation shield, air cooling, fixture design for accurate heating location, cleanliness, process control, etc.

Applications

Automation Induction Brazing System can be Equipped:

- Temperature Control

- Auto Loading & Feeding of work pieces in variety method

- Auto Feeding of solder and flux

- Version Inspection for Feeding and Brazing Location of Work piece

- Air Cooling or Water Cooling after Brazing

- Nitrogen Protection during Brazing

- Safety Light Curtain

Our Clients

Industries of Induction Heating application

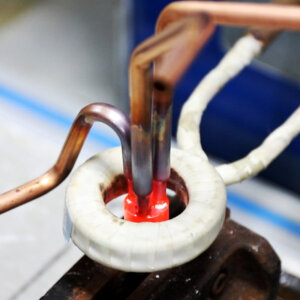

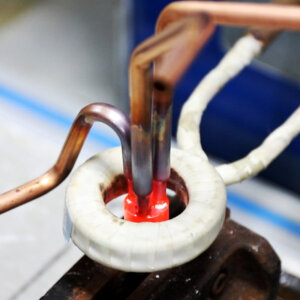

Automation Induction Brazing Equipment can be customized design for various brazing processes, such as air conditioning refrigeration valve components, refrigerator/freezer tubing components, solar energy fittings, compressor parts, washing machines (pipe-to-pipe connections, pipe-to-shell connections, pipe-to-valve connections), automobile evaporators, compressor connections, short-circuit rings on motors, and other brazing processes.

Copper Pipe Brazing

Induction Brazing

Aluminum Induction Brazing

Copper-SS Induction Brazing

Automated Induction Brazing System is widely applied in industries such as refrigeration and HVAC, household appliances, automotive, electrical motor, renewable industrial and medical devices.

Industries of Induction Heating application

1. How to choose the induction heating machine?

Please tell us with the dimensions and heating area of workpiece, heating temperature and heating time, as well as any specific requirement of heating process, our experience sales will recommend the appropriate induction heating equipment.

2. Can we see the heating test before purchase induction heater?

Customs can send the workpiece to us for heating testing in our laboratory, and decide whether purchase HCGP induction machine after received the heating testing video and report.

3. How about the service of installation and commission?

The details manual and guide for installation and commission with picture and video will be sent to our customers. Most of our customers can complete installation and commission on their own follow our instructions. We still provide paid on-site installation service.

4. The operation manual provides work standards for regular maintenance and guidance for dealing common fault. we also help you manage your spare parts inventory.

5. How can customer get service when the machine get problem?

We provide 7x24h online technical support and repair service as well as on-site service.

6. Can you provide repair parts for a long time?

Yes, we will help our customer manage their spare parts inventory.

7. Can you help us design coil for our new produces?

We offer different coil service:

- Coil design with pre-purchase heating testing

- Coil design for different heating workpieces when purchasing induction equipment

- Coil design for customers when they developing new products

- Guide customers to make coils on their own

Hongchuang High Frequency

Hongchuang High Frequency