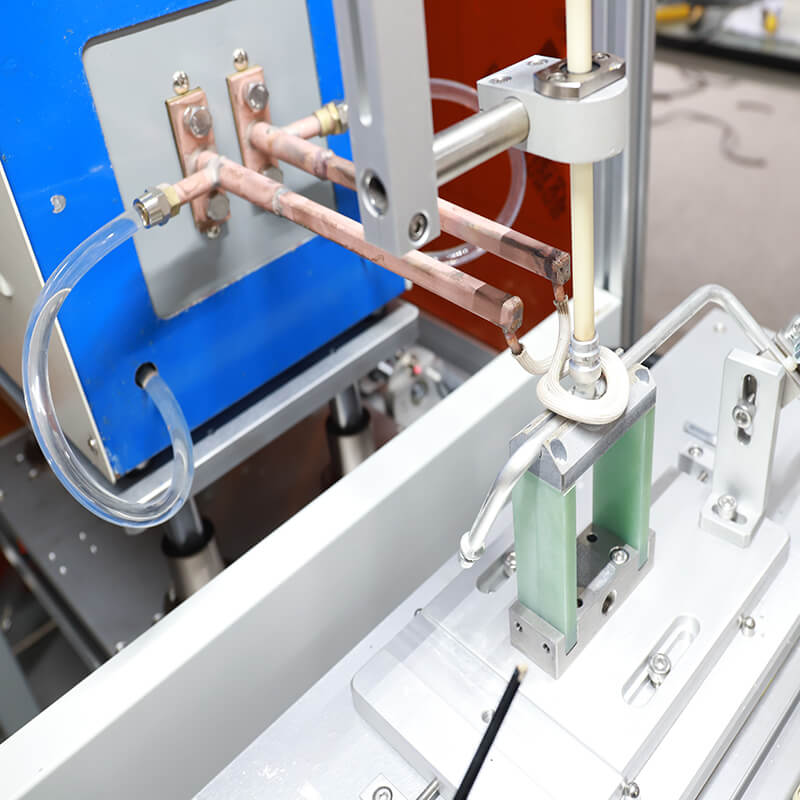

This induction aluminum brazing equipment is custom design regarding to the aluminum brazing process, the shape of brazing parts and the requirement of productivity & loading.

Feature

- Precise temperature control: In collaboration with the manufacturer,we have jointly developed infrared thermometers with a measurement accuracy of ±1% Measuring rangefor aluminum material, Closed-loop control system with PID controller, achieving precise temperature control during induction heating process.

- Accurate heating: Heating time can be accurate to 0.1 seconds.

- Data Storage: Multiple processparameters storage with one-click for data retrieval.

- Induction coil design with years aluminum brazing experience, only the target heating area heated without hurt base material of workpiece.

- Well-designed workpiece fixtures enable more stable and precise aluminum brazing quality.

Application

Advantage:

- Aluminum Brazing system with induction offer better joint quality duo to its reliability, repeatability.

- High heating efficient increase throughput of brazing.

- PLC control and data storage of induction equipment improve the brazing process.

- Precise management of heating temperature ensure better quality of aluminum brazing.

Our Clients

Induction Aluminum Brazing Device is suitable for automotive air-conditioning and refrigeration accessories assembly, such as: induction brazing of evaporator outlet pipes, single-tube pressure plates, double-tube pressure plates, air-conditioning pipelines, sight glass, aluminum distributors, etc. Induction heating is also good for aluminum brazing in the assembly of new energy vehicles and bicycle.

Brazing of Bike Fittings

Aluminum Induction Brazing

Aluminum Brazing

Induction Brazing

Induction Aluminum Brazing Equipment is widely applied in industries such as refrigeration and HVAC, household appliances, automotive, electrical motor, renewable industrial and Bicycle Industrial.

Industries of Induction Heating application

1. How to choose the induction heating machine?

Please tell us with the dimensions and heating area of workpiece, heating temperature and heating time, as well as any specific requirement of heating process, our experience sales will recommend the appropriate induction heating equipment.

2. Can we see the heating test before purchase induction heater?

Customs can send the workpiece to us for heating testing in our laboratory, and decide whether purchase HCGP induction machine after received the heating testing video and report.

3. How about the service of installation and commission?

The details manual and guide for installation and commission with picture and video will be sent to our customers. Most of our customers can complete installation and commission on their own follow our instructions. We still provide paid on-site installation service.

4. The operation manual provides work standards for regular maintenance and guidance for dealing common fault. we also help you manage your spare parts inventory.

5. How can customer get service when the machine get problem?

We provide 7x24h online technical support and repair service as well as on-site service.

6. Can you provide repair parts for a long time?

Yes, we will help our customer manage their spare parts inventory.

7. Can you help us design coil for our new produces?

We offer different coil service:

Coil design with pre-purchase heating testing

Coil design for different heating workpieces when purchasing induction equipment

Coil design for customers when they developing new products

Guide customers to make coils on their own

Induction Heating Coils

Hongchuang High Frequency

Hongchuang High Frequency