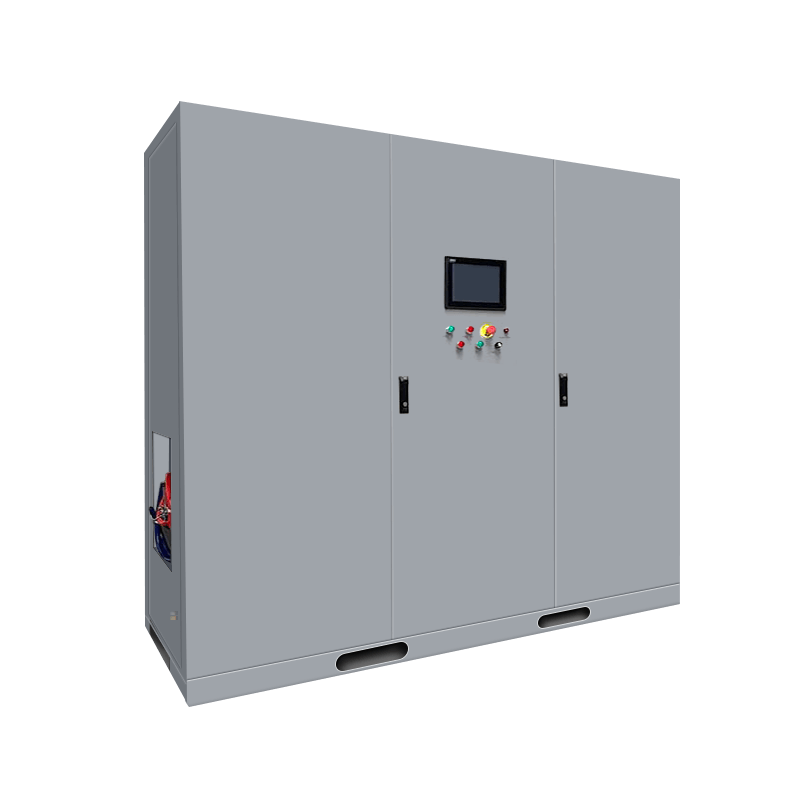

Característica:

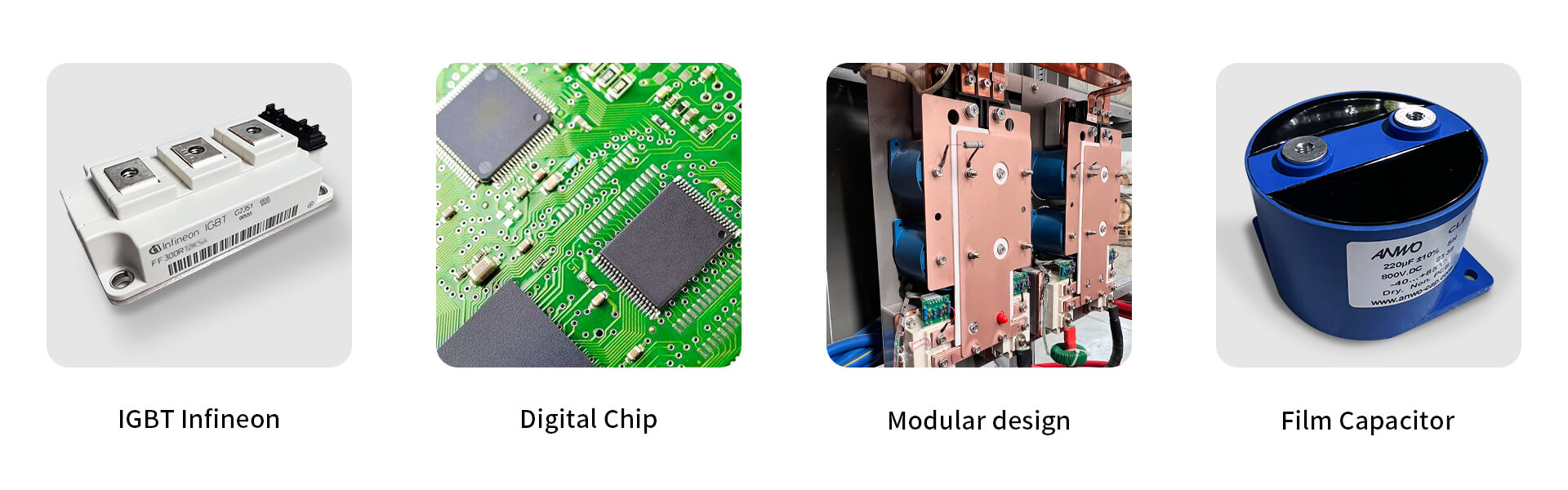

- Alta eficiencia con tecnología inversor IGBT & Circuito de resonancia serie LC, Mejora la alta eficiencia.

- Digital chip technology, the control of power output and the detection of faults are entirely done through digital chip control, greatly reducing power variations or faults caused by environmental factors and usage time. This significantly enhances the reliability and stability of the equipment.

- Modular design, with over 80% of components on module groups, allows for interchangeable module groups across all models, making maintenance and repair simple and convenient, while keeping costs low.

- Automatic frequency tracking technology enables devices to operate at the optimal frequency state. The working status of the equipment is automatically detected

- Reserve AD, DA interfaces to provide analog signal transmission, while also supporting digital signal transmission using the MODBUS protocol, RS-485. Induction heater is enables easy integration with PLC, CNC control, and compatible equipment, allowing for seamless automation control.

- HCGP Induction Generator can be designed as subharmonic resonance according to shape and material of the workpiece. Subharmonic resonance technology allows induction power supply to have a wide range of impedance matching, induction heater can work with different coils at optimal operation during heating non-magnetic and irregularly shaped workpieces at high heating efficiency.

Ventaja:

- Energy saving 10%-30% comparing with SCR Transistors induction generator.

- High heating Efficiency increase production yield.

- Simple and practical equipment design, high cost-effectiveness.

- El convertidor de inducción comienza a calentar en cualquier condición de carga y funcione a plena carga para 24 horas.

- Completa de la función de protección que garantiza una alta confiabilidad del equipo de inducción.

- Provide multiple signal transmission such as pulse signal, digital signal, RS-485 etc, El calentador de inducción HCGP es más fácil de integrarse con otra máquina y lograr la automatización de la producción.

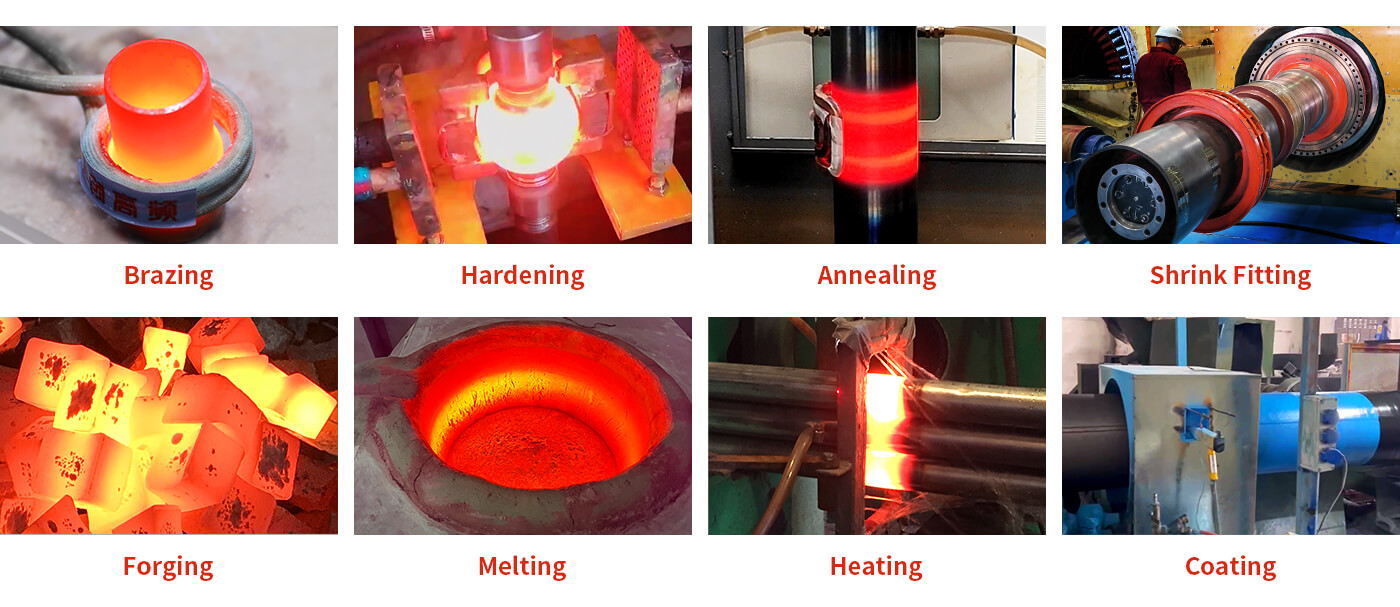

Aplicaciones

Forja de inducción & formando, Soldadura por inducción, Ajuste retráctil, Endurecimiento por induccion, Induction Heat Treatment, Fusión por inducción, Recubrimiento de inducción

Nuestros clientes

Hongchuang alta frecuencia

Hongchuang alta frecuencia