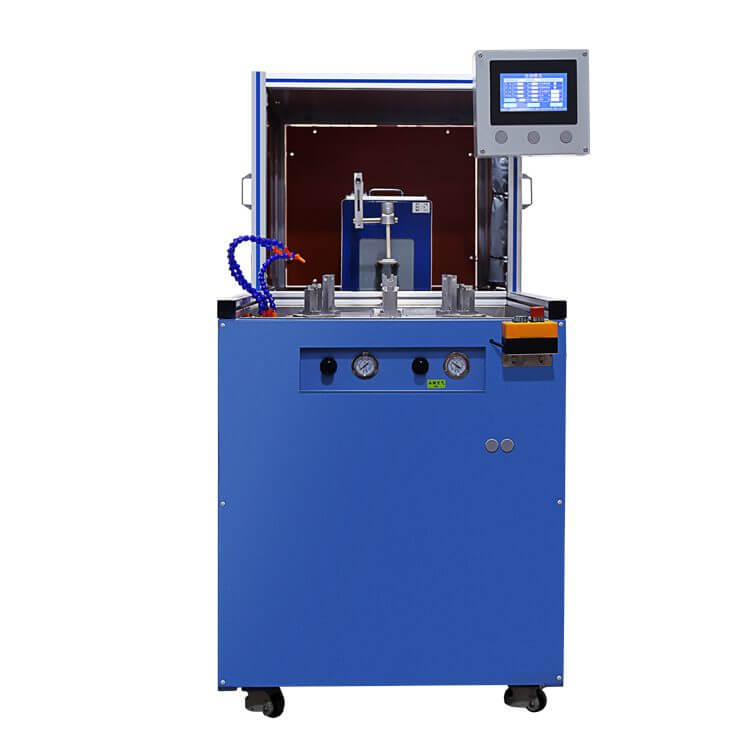

The induction brazing equipment suitable for brazing of air-conditioning and refrigeration fittings, seperti: sambungan paip, paip ekor pengedar, injap solenoid dan kelengkapan lain. Ia juga sesuai untuk memateri loyang, tembaga, Keluli tahan karat, kelengkapan paip aluminium dengan paip lurus di hujung atas ke saluran paip. Peralatan Brazing Induksi juga boleh disesuaikan mengikut bentuk paip yang berbeza.

Ciri-ciri:

- Induction brazing system can be manual, separa automatik atau automatik mengikut keperluan pelanggan.

- Stesen kerja mesin pemateri tiub aruhan adalah stesen tunggal yang disesuaikan, dua stesen dan beberapa stesen untuk memenuhi keperluan kadar pengeluaran yang berbeza.

- Kawalan digital membolehkan mesin pematerian induksi mudah disepadukan dengan barisan pengeluaran.

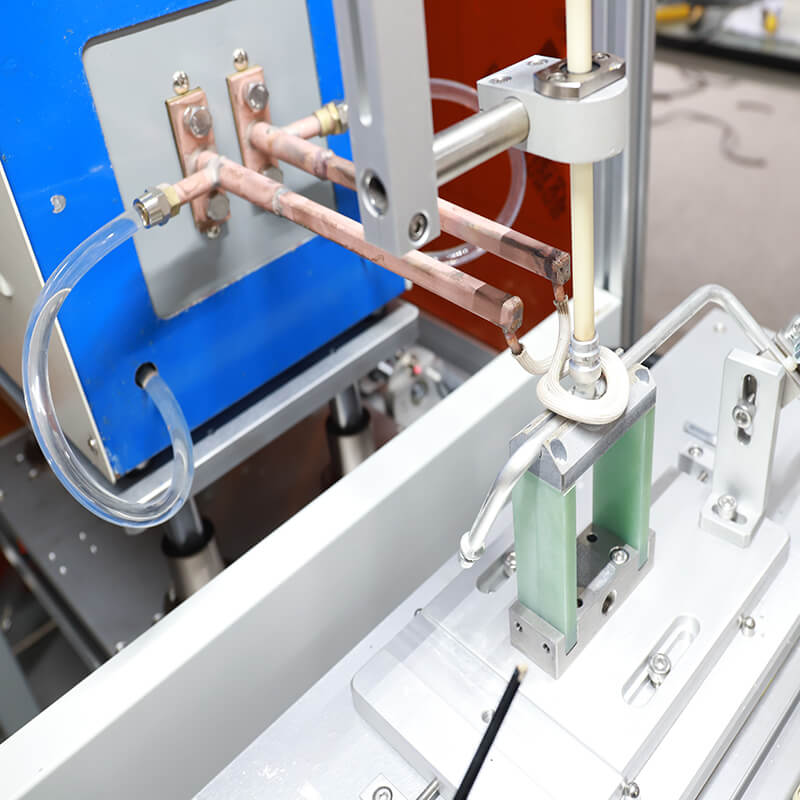

- Reka bentuk khususnya memastikan proses pematerian berjaya seperti gas lengai untuk perisai operasi, penyejukan udara, penambahan fluks, reka bentuk lekapan untuk lokasi pemanasan yang tepat, kebersihan, kawalan proses, dll.

Aplikasi

Kelebihan:

- tepat, pemanasan yang disasarkan meningkatkan pengeluaran pengeluaran.

- Pemanasan yang boleh dipercayai dan tepat memastikan kualiti braze yang konsisten setiap masa.

- Pemanasan aruhan ialah tiada pemanasan sentuhan tanpa nyalaan atau relau panas, menyediakan persekitaran kerja yang selamat.

- Pemanas aruhan padat menjimatkan ruang di kedai kerja.

Pelanggan Kami

Induction Brazing System is suitable for automotive air-conditioning and refrigeration accessories assembly, seperti: pematerian aruhan bagi paip keluar penyejat, plat tekanan satu tiub, plat tekanan dua tiub, saluran paip penghawa dingin, kaca penglihatan, pengedar aluminium, dll. Pemanasan aruhan juga bagus untuk pematerian aluminium dalam pemasangan kenderaan tenaga baharu dan basikal.

Pateri Tembaga

Pateri Aluminium

Pateri Bersama Keluli tahan karat tembaga

Pateri Bahagian Aluminium

Peralatan Brazing Induksi digunakan secara meluas dalam industri seperti penyejukan dan HVAC, peralatan rumah tangga, Automotif, Motor elektrik, Perindustrian Perindustrian dan Basikal Boleh Diperbaharui.

Industri aplikasi Pemanasan Induksi

1. Cara memilih mesin pemanasan induksi?

Tolong beritahu kami dengan dimensi dan kawasan pemanasan bahan kerja, suhu pemanasan dan masa pemanasan, serta keperluan proses pemanasan tertentu, Jualan pengalaman kami akan mengesyorkan peralatan pemanasan induksi yang sesuai.

2. Bolehkah kita melihat ujian pemanasan sebelum membeli pemanas induksi?

Kastam boleh menghantar bahan kerja kepada kami untuk ujian pemanasan di makmal kami, dan memutuskan sama ada membeli mesin induksi HCGP setelah menerima video ujian pemanasan dan laporan.

3. Bagaimana dengan perkhidmatan pemasangan dan komisen?

Butiran manual dan panduan untuk pemasangan dan komisen dengan gambar dan video akan dihantar kepada pelanggan kami. Sebilangan besar pelanggan kami dapat menyelesaikan pemasangan dan komisen dengan sendiri mengikuti arahan kami. Kami masih menyediakan perkhidmatan pemasangan di tapak berbayar.

4. Manual Operasi menyediakan piawaian kerja untuk penyelenggaraan dan bimbingan biasa untuk menangani kesalahan biasa. Kami juga membantu anda menguruskan inventori alat ganti anda.

5. Bagaimana pelanggan boleh mendapatkan perkhidmatan apabila mesin mendapat masalah?

Kami menyediakan sokongan teknikal dalam talian 7x24j dan perkhidmatan pembaikan serta perkhidmatan di tapak.

6. Bolehkah anda menyediakan bahagian pembaikan untuk masa yang lama?

Ya, Kami akan membantu pelanggan kami menguruskan inventori alat ganti mereka.

7. Bolehkah anda membantu kami mereka bentuk gegelung untuk hasil baharu kami?

Kami menawarkan perkhidmatan gegelung yang berbeza:

- Reka bentuk gegelung dengan ujian pemanasan pra-pembelian

- Reka bentuk gegelung untuk bahan kerja pemanasan yang berbeza semasa membeli peralatan induksi

- Reka bentuk gegelung untuk pelanggan ketika mereka membangunkan produk baru

- Membimbing pelanggan untuk membuat gegelung sendiri

Gegelung pemanasan induksi

Frekuensi Tinggi Hongchuang

Frekuensi Tinggi Hongchuang