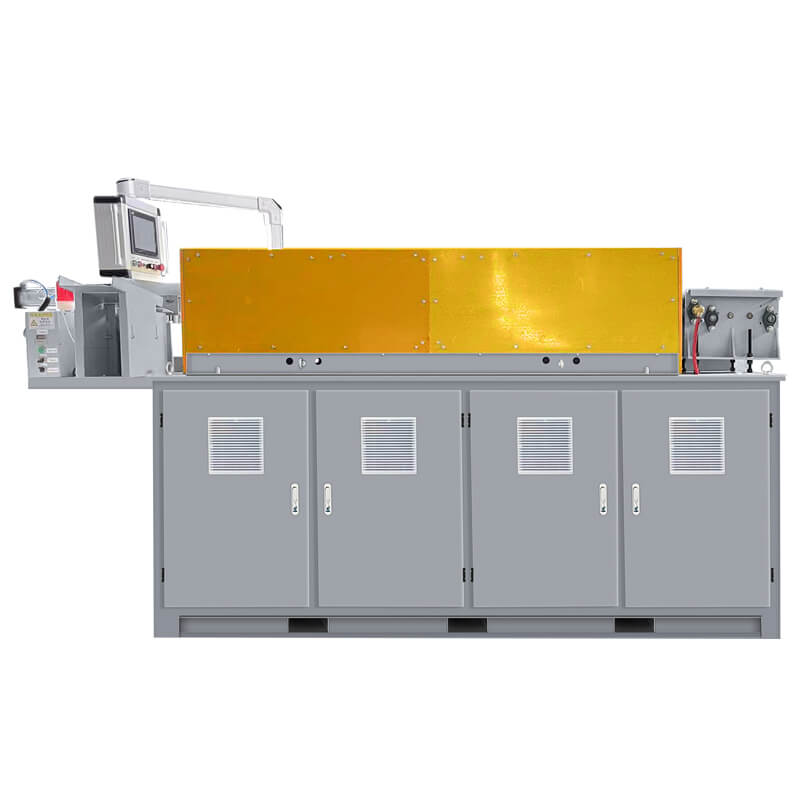

Induction bar-end heater uses different types of induction coils to heat multiple bar end with many sizes and shapes of parts. The application of Bar and pipe end or midsection heating is for bending, forming and forging.

特徴 & Advantages:

- Efficient and rapid heating increase production rate, minimize oxidation of billet, extend the life of forging die.

- Controllable and accurate heating temperature improve the forging quality. reduce oxide scaling of billet.

- Induction forging systeme is more effective and energy-saving with IGBT inverter technology and series resonance technology.

- Induction billet heating system for forge effectively heat various material of billets such as steel, 銅, 真鍮, aluminum and stainless steel.

- Controllable induction heating ensure uniform heating of throughout billet from the surface to the core.

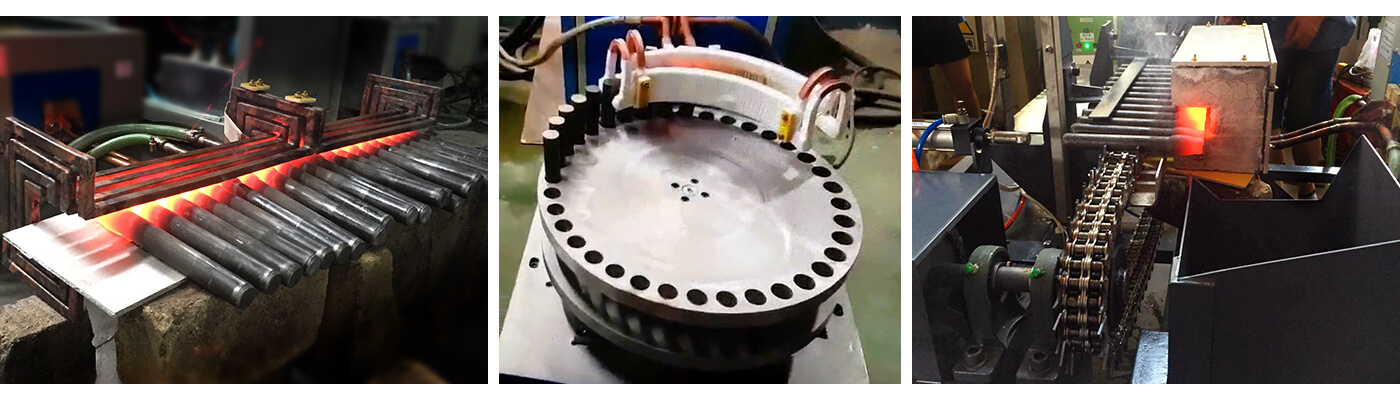

Induction Partial Forging Process

Optional Devices:

応用: Induction Partial Forging & 形にする

Our customs

香港の高頻度

香港の高頻度