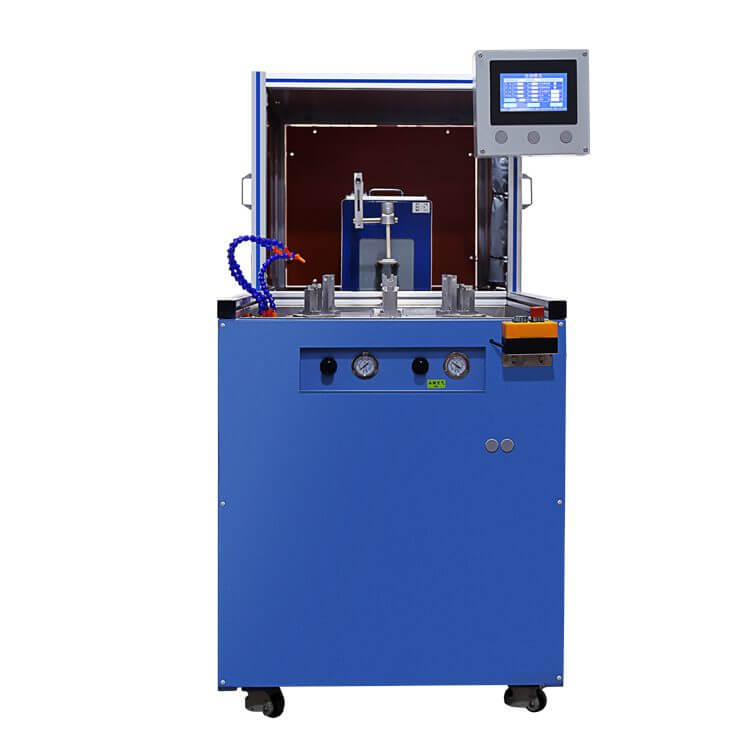

This automated Induction Brazing system particularly design for electrical contact brazing such as silver contacts to copper bar. Normally this induction machine used for AC contactor assembly.

特徴:

- Multiple-segment settings for induction heating: There are 5 segment basically and can be customized according to customer requirements.

- 正確な温度制御: Infrared thermometers with a measurement accuracy of ±1% Measuring range, Closed-loop control with PID controller, achieving precise temperature control during induction brazing process.

- 正確な加熱: Heating setting time can be accurate to 0.1 秒.

- データストレージ: Multiplebrazing process parameters storage with one-click for data retrieval

- PLC control with user friendly interface, operation easy without more skill requirement of operator.

- Particularlydesign meet various brazing process such as inert gas for operation shield, air cooling, flux addition, fixture design for accurate heating location, cleanliness, process control, 等.

- Induction brazing machine can be linear drive, rotary index type and other types for variety workpieces loading and composite process requirement.

アプリケーション

Automation Induction Brazing System can be Equipped:

- Temperature Control

- Auto Loading & Feeding of work pieces in variety method

- Auto Feeding of solder and flux

- Version Inspection for Feeding and Brazing Location of Work piece

- Air Cooling or Water Cooling after Brazing

- Nitrogen Protection during Brazing

- Safety Light Curtain

お客様

香港の高頻度

香港の高頻度