Integrated Chiller with induction heating system, installation and usage are more convenient. Integrated Portable Induction Equipment with Chiller is widely applied in industries such as refrigeration and HVAC, peralatan rumah tangga, pembuatan kereta, dan peranti perubatan.

Kelebihan:

- Mobiliti Mudah: Handheld heating equipment enables induction brazing for complex and hard-to-reach workpieces or workshop positions with small size, mobiliti mudah, dan operasi mudah.

- Kebolehkawalan yang Baik: Kawalan tepat pemanasan aruhan meminimumkan risiko terlalu panas semasa pemanasan, mengelakkan kerosakan pada komponen yang dipanaskan dan meningkatkan kelayakan produk

- Operasi Tepat: Pemanasan yang stabil dan bebas getaran memastikan kedudukan kimpalan yang tepat. Ia boleh mengimpal logam dengan diameter minimum 0.1mm dan induktor boleh disesuaikan mengikut bentuk bahan kerja yang berbeza..

- Operasi yang Mudah: Pemanasan aruhan boleh diproses di tempat yang menyimpan bahan kerja pemanasan, hanya menggerakkan kepala pemanas untuk pematerian atau proses lain.

- Pengurangan Kos: Proses pemanasan yang cekap dan tepat secara aruhan memastikan kadar kelayakan kimpalan, meminimumkan pembaziran, kerja semula, dan penggunaan tenaga.

- Persekitaran Kerja yang Selesa: Pemanasan aruhan adalah senyap dan tanpa menyebabkan kenaikan suhu persekitaran sekeliling.

Permohonan

Pelanggan kami

Aplikasi:

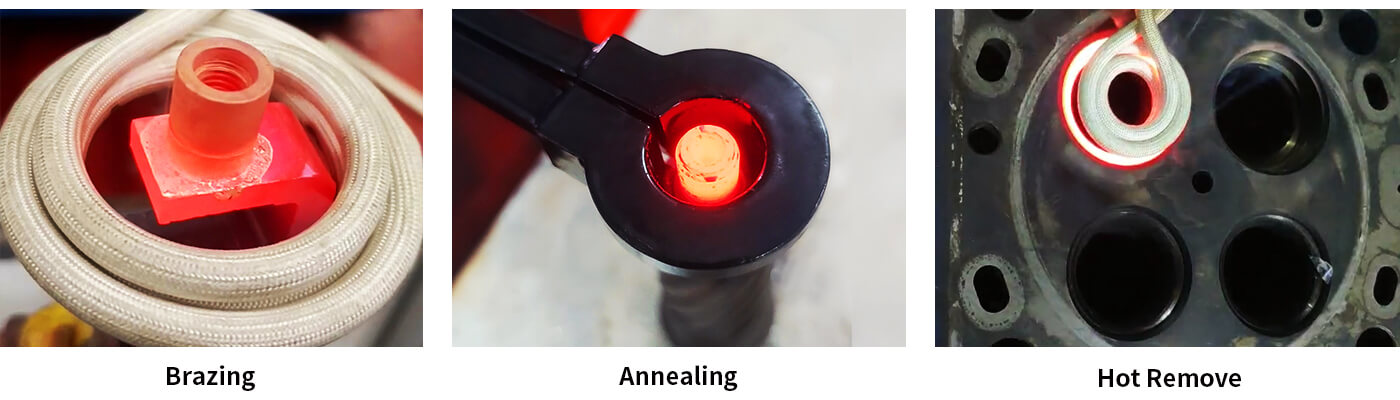

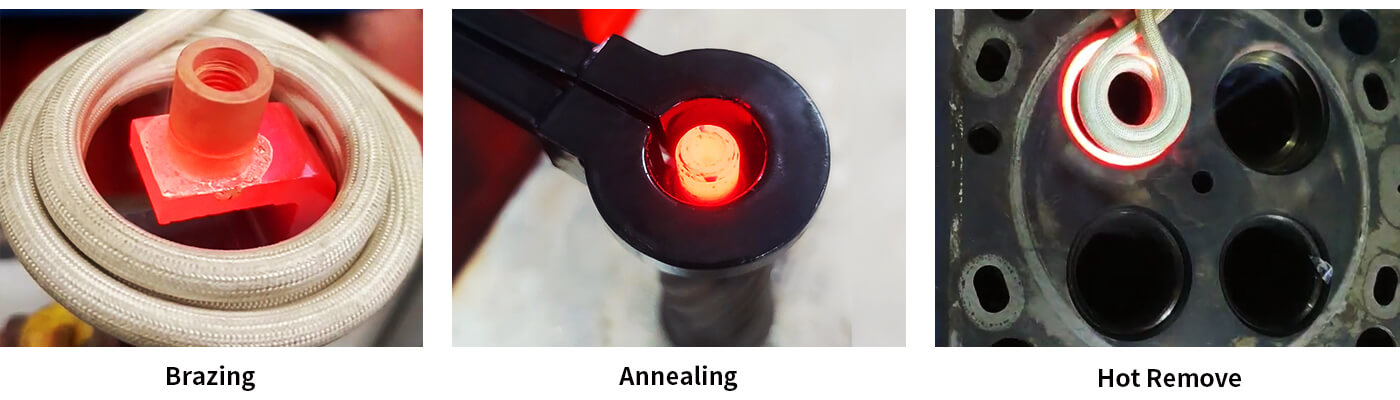

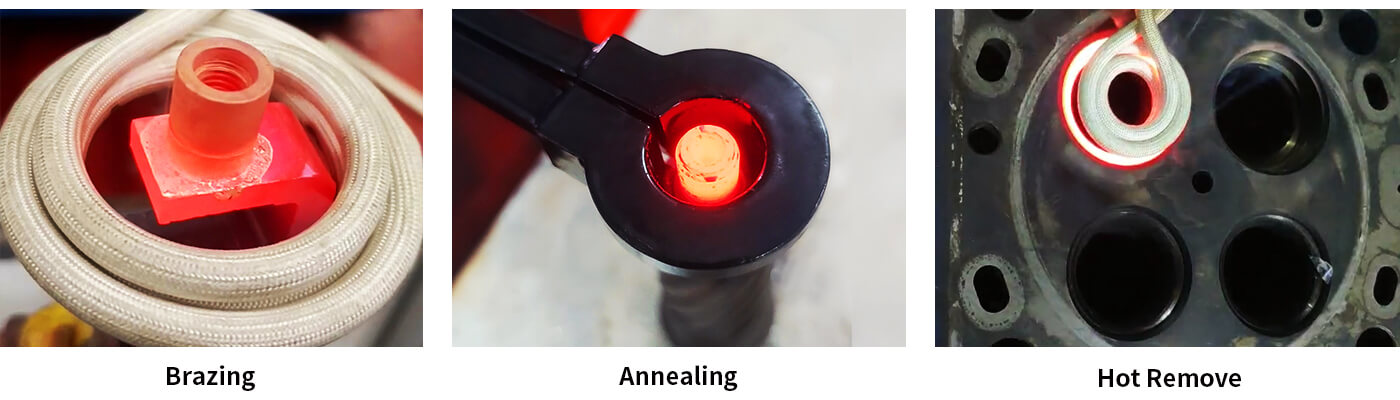

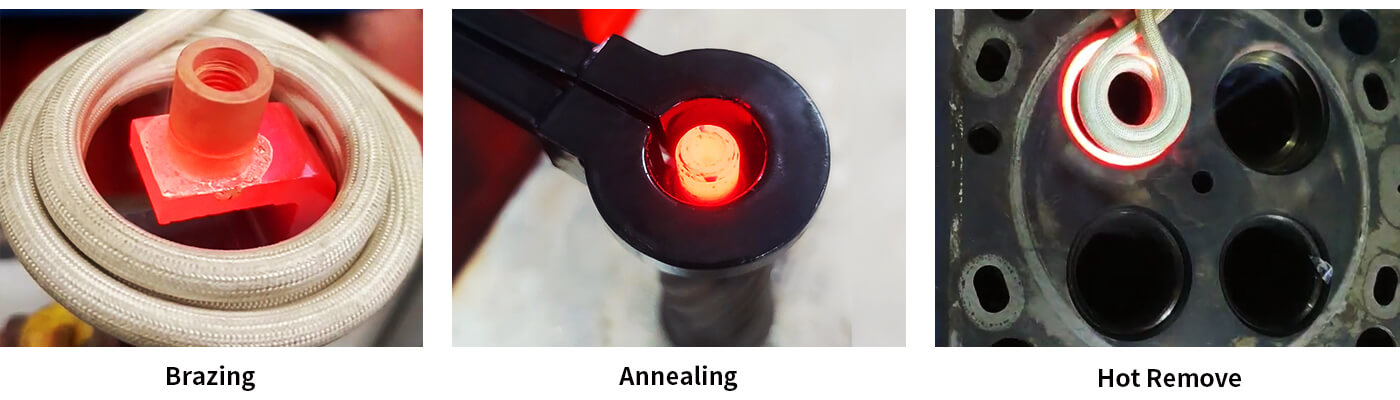

Mobile Induction Heating Equipment is special design for flexible heating in brazing, mengecilkan pemasangan, penyepuhlindapan, hot remove, per-heating etc.

1. Cara memilih mesin pemanasan induksi?

Tolong beritahu kami dengan dimensi dan kawasan pemanasan bahan kerja, suhu pemanasan dan masa pemanasan, serta keperluan proses pemanasan tertentu, Jualan pengalaman kami akan mengesyorkan peralatan pemanasan induksi yang sesuai.

2. Bolehkah kita melihat ujian pemanasan sebelum membeli pemanas induksi?

Kastam boleh menghantar bahan kerja kepada kami untuk ujian pemanasan di makmal kami, dan memutuskan sama ada membeli mesin induksi HCGP setelah menerima video ujian pemanasan dan laporan.

3. Bagaimana dengan perkhidmatan pemasangan dan komisen?

Butiran manual dan panduan untuk pemasangan dan komisen dengan gambar dan video akan dihantar kepada pelanggan kami. Sebilangan besar pelanggan kami dapat menyelesaikan pemasangan dan komisen dengan sendiri mengikuti arahan kami. Kami masih menyediakan perkhidmatan pemasangan di tapak berbayar.

4. Bagaimana pelanggan boleh mendapatkan perkhidmatan apabila mesin mendapat masalah?

Kami menyediakan sokongan teknikal dalam talian 7x24j dan perkhidmatan pembaikan serta perkhidmatan di tapak.

5. Bolehkah anda menyediakan bahagian pembaikan untuk masa yang lama?

Ya, Kami akan membantu pelanggan kami menguruskan inventori alat ganti mereka.

6. Bolehkah anda membantu kami mereka bentuk gegelung untuk hasil baharu kami?

Kami menawarkan perkhidmatan gegelung yang berbeza:

- Reka bentuk gegelung dengan ujian pemanasan pra-pembelian

- Reka bentuk gegelung untuk bahan kerja pemanasan yang berbeza semasa membeli peralatan induksi

- Reka bentuk gegelung untuk pelanggan ketika mereka membangunkan produk baru

- Membimbing pelanggan untuk membuat gegelung sendiri

Gegelung pemanasan induksi

Frekuensi Tinggi Hongchuang

Frekuensi Tinggi Hongchuang